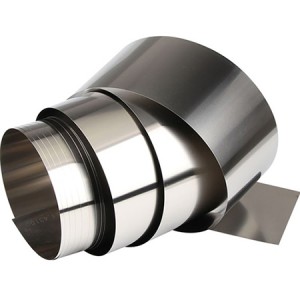

4J29-Kovar ingxubevange strip Kovar ibha / kovar sheet / kovar ityhubhu

Amagama oRhwebo oluQhelekileyo:Kovar Alloy,4J29,UNS K94610(FeNi29Co17),29HК Kovar,KV-1,29HК-BИ,Werkstoff Nr.1.3981

Le alloy kwakhona caleed Glass itywinwe kwaye ilawulwa ialloy yokwandisa,Ingxubevange ine ai-coefficient yokwandiswa komgcaefana naleyo ye-silicon boron iglasi eqinile kwi-20-450 ° C, aindawo ephezulu yeCurie, kunye nokuzinza kolwakhiwo oluphantsi lobushushu obuphantsi.Ifilimu ye-oxide ye-alloy ixinene kwaye ingaba kakuhlemanzingeiglasi.Ayidibanisi ne-mercury kwaye ifanelekile ukusetyenziswa kwiimitha zokukhupha i-mercury-containing.Yeyona nto iphambili yokutywinwa kwesakhiwo sezixhobo zokufunxa zombane.

| C | Cr | Ni | Mo | Si | Mn | P | S | Fe | Co | Cu |

| ≤0.03 | ≤0.2 | 28.5-29.5 | ≤0.2 | ≤0.3 | ≤0.5 | ≤0.02 | ≤0.02 | ibhalansi | 16.8-17.8 | ≤0.2 |

| Ubuninzi (g/cm3) | I-Thermal conductivity (W/m·K) | Ukuxhathisa koMbane(μΩ·cm) |

| 8.3 | 17 | 45 |

| Amabanga engxubevange

| Umndilili wokwandiswa komgca womlinganiso a,10-6/ oC | |||||||

| 20-200 oC | 20-300 oC | 20-400 oC | 20-450 oC | 20-500 oC | 20-600 oC | 20-700 oC | 20-800 oC | |

| kovar | 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 |

I-Kovar i-avareji yokwandisa i-coefficient yomgca kumgca

| Amabanga engxubevange | Inkqubo yonyango lobushushu bomzekelo | Umndilili wokwandiswa komgca womlinganiso α,10-6/ oC | ||

| Kovar | 20-300 oC | 20-400 oC | 20-450 oC | |

| Kwi-atmosfera ye-hydrogen ifudunyezwe ukuya kuma-900 ± 20 oC, ukugquma i-1h, emva koko ifudunyezwe ukuya kwi-1100 ± 20 oC, ukugquma yi-15min, ukuba ingabi ngaphezu kwe-5 oC/min isantya sokupholisa ukuya ngaphantsi kwe-200 oC ikhululiwe. | ----- | 4.6-5.2 | 5.1-5.5 | |

Kovar i-coefficient yokwandisa eqhelekileyo

| Amabanga engxubevange | Umndilili wokwandiswa komgca womlinganiso a,10-6/ oC | |||||||

| Kovar | 20-200oC | 20-300 oC | 20-400oC | 20-450oC | 20-500oC | 20-600oC | 20-700oC | 20-800oC |

| 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 | |

I-Kovar Alloy efumanekayo yeeMveliso kwiiNyithi zeSekonic

Kutheni uInonel Kovar ?

I-1.Kovar inosetyenziso olubanzi kushishino lwe-electronics, njengamalungu esinyithi adityaniswe kwiimvilophu zeglasi enzima.Ezi nxalenye zisetyenziselwa izixhobo ezifana neetyhubhu zamandla kunye neetyhubhu ze-X-ray, njl.

I-2.Kwishishini le-semiconductor i-kovar isetyenziswa kwiipakethi ezitywinwe nge-hermetically kuzo zombini izixhobo zesekethe ezidibeneyo kunye ne-discrete.

I-3.Kovar inikezelwa kwiintlobo ezahlukeneyo zokuququzelela ukuveliswa ngokufanelekileyo kweendawo ezahlukeneyo zetsimbi.Ineempawu zokwandisa ubushushu obuhambelana nezo zeglasi eqinileyo.Isetyenziselwa ukudityaniswa kokwandiswa okuhambelanayo phakathi kwesinyithi kunye neglasi okanye iiseramikhi.

I-4.Kovar ingxubevange yi-vacuum enyibilikisiweyo, i-iron-nickel-cobalt, i-alloy yokwandisa ephantsi okwakhiwa kweekhemikhali kulawulwa ngaphakathi kwemida emxinwa ukuze kuqinisekiswe iipropati ezichanekileyo ezifanayo zokwandisa i-thermal.Ulawulo lomgangatho olubanzi luqashwe ekwenzeni le ngxubevange ukuqinisekisa iimpawu ezifanayo zomzimba kunye noomatshini ukuze kube lula kumzobo onzulu, ukunyathela kunye nomatshini.

Indawo yeSicelo seKovar Alloy:

● I-alloy ye-Kovar isetyenziselwe ukwenza izitywini ze-hermetic kunye neeglasi zePyrex ezinzima kunye nezixhobo ze-ceramic.

● Le alloy ifumene ukusetyenziswa okubanzi kwiityhubhu zamandla, iityhubhu ze-microwave, ii-transistors kunye ne-diode.Kwiisekethe ezidibeneyo, isetyenziswe kwi-flat pack kunye ne-double-in-line package.