Ubushushu obuphakamileyo beNtwasahlobo yeDiskhi yaseNtwasahlobo yamaza eNtwasahlobo

Intwasa yobushushu obuphezulu:

Intlakohlaza yinxalenye yomatshini esebenzisa ukunwebeka ukusebenza.Amalungu enziwe ngezinto ezi-elastic aguqukayo phantsi kwesenzo samandla angaphandle, kwaye abuyele kwisimo sawo sokuqala emva kokususa amandla angaphandle.Ikwasetyenziswa njenge "spring".Ngokuqhelekileyo yenziwe ngentsimbi yasentwasahlobo.Iindidi zemithombo ziyinkimbinkimbi kwaye zihlukeneyo.

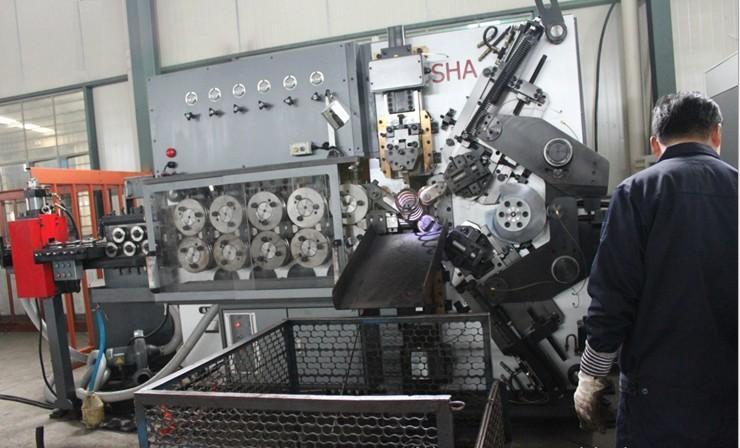

Inkampani yethu iManyene neeFactory zaseNtwasahlobo eziPhambili zemveliso kwaye zibonelela ngeSprings zobushushu obuphezulu

• IiMathiriyeli zaseNtwasahlobo zobushushu obuphezulu:

SUS304,SUS316, SUS631/17-7PH, SUS632/15-7Mo, 50CrVA, 30W4Cr2VA,

I-Inconel X-750, Ikhoneli 718, I-Nimonic90, I-Incoloy A286(SUH660)

• Iindidi zaseNtwasahlobo:

→Imithombo yoxinzelelo →Intlakohlaza eyandisiweyo

→Intlakohlaza yeTorsion →Intlakohlaza egotshwayo

♦ Intwasahlobo yamaza ♦ SkrolaIntwasahlobo♦ I-Disc Spring

♦ I-Ring Spring ♦ Intwasahlobo eKhethekileyo, njl

| Iintlobo zezinto eziphathekayo | Igama leMathiriyeli | Ubushushu beSicelo esiPhezulu°C |

| yenziwe ngentsimbi eshayinayo | SUS304/SUS316 | 200 |

| SUS631/17-7PH | 370 | |

| SUS632/15-7Mo | 470 | |

| I-alloy spring steel | 50CrVA | 300 |

| 30W4Cr2VA | 500 | |

| Ubushushu obuphezulu be-nickel base alloy | I-Incoloy A286(GH2132) | 600 |

| I-Inconel X-750(GH4145) | 600 | |

| I-Inconel 718 (GH4169) | 690 | |

| I-Nimonic90(GH4090) | 800 (γ<0.2) | |

| GH4099 | 1000 (γ<0.1) |

♦♦♦ Imithombo yeDisc♦♦♦

Zisetyenziswa ikakhulu kwiivalvu, iiflange, ii-clutches, iziqhoboshi, iziguquli zetorque, iswitshi ekwi-High-voltage, ukuqiniswa kwebholiti, inkxaso yemibhobho, i-shockproof kunye nemimandla eyothusayo.bavelise ngokuhambelana ne-DIN EN16983 (DIN2093).

Ubukhulu obungaphandle buqala kwi-6mm ukuya kwi-1000mm.

Izixhobo ziqukai-alloy steel 51CrV4, i-carbon steel SK85, i-1074;

• Insimbi engenasici ye-ASTM301, 304, 316, 17-7PH, 17-4PH, 15-7Mo;

• Intsimbi ekwazi ukumelana nobushushu H13, X30WCrV53, X22CrMoV12-1, X39CrMo17-1;

• I-inconel X750 ye-Inconel X750, i-Inconel X718, i-Nimonic 90, njl.

♦♦♦ Imithombo yamaza♦♦♦

I-Wave spring yintsimbi ebhityileyo emile okwesangqa ehlanganiswe ngamaza amaza kunye neentlambo ezininzi.Imithombo yamaza isetyenziswa kakhulu kwiimotor, oomatshini belaphu, izixhobo zehydraulic, iimoto kunye namanye amashishini.Ufakelo oluphambili kunye neenkcukacha (ubungakanani obuqhelekileyo) begumbi lokuthwala zifanelekile.Okanye emngxunyeni, indawo yokufakela incinci, kwaye inomsebenzi okhethekileyo wokunciphisa ingxolo kunye nokunciphisa i-vibration.

Ubukhulu obungaphandle buqala kwi-6mm ukuya kwi-1000mm.ubukhulu buqala kwi-0.4mm ukuya kwi-5.0mm.

Ukhuseleko lomhlwa

- I-Phosphating

- Ukugalela oomatshini

- Nickel plated

- Jiaomei

Zineempawu ze-deformation encinci kunye nomthwalo omkhulu.Ikwanazo ezi mpawu zilandelayo.

- Imithombo yediski inokufumana iimpawu ezahlukeneyo zomthwalo ngokusebenzisa indibaniselwano eyahlukeneyo yoguqulo kunye nokugqithelana.

- Xa kuthelekiswa neminye imithombo, imithombo yediski ithatha indawo encinci.

- Xa amaphepha amaninzi esetyenziswa ngokudibeneyo, umphumo wokudambisa uyanda.

- Xa isetyenziswe ngokufanelekileyo, ayiyi kukhubaza okanye iphuke.

- Ubomi obude bokudinwa.

| Izinto zaseNtwasahlobo | ITemp yoMsebenzi | Tensile strength | Imodyuli ye-Elastic KN//mm2 | IKhemistri% | ||||||||||||||||||

| °C | N/mm2 | RT°C | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C | C | Si | Mn | P | S | Cr | Ni | Abanye | ||||||

| T8A SK85 | -50 ukuba +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.80-0.09 | ≤ 0.35 | ≤ 0.50 | ≤ 0.03 | ≤ 0.03 | ≤ 0.20 | ≤ 0.25 | Cu≤0.30 | |||||

| 50CrV4 SUP10 | -50 ukuya +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.47-0.55 | ≤ 0.4 | 0.71.1 | ≤ 0.025 | 0.025 | 0.9 1.2 | ≤ 0.4 | V:0.1 0.25Mo≤ 0.1 | |||||

| C75 | -50 ukuba +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.70-0.80 | 0.15-0.35 | 0.60 0.90 | ≤ 0.025 | 0.025 | ≤ 0.4 | ≤ 0.4 | Mo≤ 0.1 | |||||

| 60Si2Mn SUP6 | -50 ukuya +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.56-0.64 | 1.50-2.0 | 0.6 0.9 | ≤ 0.035 | 0.035 | ≤ 0.35 | ≤ 0.35 | ||||||

| X 10CrNi 18-8 SUS301 | -200 ukuya +200 | 1150-1500 | 190 | 186 | 180 | - | - | - | - | 0.05-0.15 | ≤ 2.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 16.0 19.0 | 6.0 9.5 | Mo≤ 0.08 | |||||

| X 5CrNi 18-10SUS304 | -200 ukuya +200 | 1000-1500 | 185 | 179 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 17.0 19.5 | 6.0 9.5 | N≤ 0.11 | |||||

| X 5CrNiMo 17-12-2 SUS316 | -200 ukuya +200 | 1000-1500 | 180 | 176 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 16.5-18.5 | 10.0 13.0 | Mo:2.0-2.5N≤ 0.11 | |||||

| X 7CrNiAl 17-7 SUS631 | -200 ukuya +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 0.7 | ≤ 1.0 | ≤ 0.04 | 0.015 | 16.0 18.0 | 6.5 7.8 | Al:0.7-1.5 | |||||

| X5CrNiCuNb 16-4 SUS630 | -200 ukuya +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 1.0 | ≤ 0.035 | 0.03 | 15.0 17.0 | 3.0 5.0 | ||||||

| X8CrNiMoAl 15-7-2 | -200 ukuya +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | 0.03 | 14.0 16.0 | 6.5 7.75 | Mo:2.0-3.0Al:0.75-1.5 | |||||

| Intsimbi X39CrMo 17-1 | -50 ukuba +400 | 1200-1400 | 215 | 212 | 205 | 200 | 190 | - | - | 0.33-0.45 | ≤ 1.0 | ≤ 1.5 | ≤ 0.04 | 0.03 | 15.5 17.5 | ≤ 1.0 | Mo: 0.7-1.3 | |||||

| X 22CrMoV 12-1 | -50 ukuba +500 | 1200-1400 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.18-0.24 | ≤ 0.5 | 0.4 0.9 | ≤ 0.025 | 0.015 | 11 12.5 | 0.3-0.8 | V: 0.25-0.35Mo:0.8-1.2 | |||||

| X30WCRV53 SKD4 | -50 ukuba +500 | ≥ 1470 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.25-0.35 | 0.15-0.30 | 0.20 0.40 | ≤ 0.035 | 0.035 | 2.2 2.5 | ≤ 0.35 | V:0.5-0.7 W: 4-5 | |||||

| X40CrMoV5-1 SKD61 | -150 ukuba +600 | 1650-1990 | 206 | 200 | 196 | 189 | 186 | 158 | - | 0.32 0.40 | 0.8 1.20 | 0.20 0.50 | ≤ 0.030 | 0.030 | 4.75 5.50 | V: 0.80-1,20Mo:1.1-.75 | ||||||

| Nickel Ikhonkco X750 | -200 ukuba +600 | ≥ 1170 | 214 | 207 | 198 | 190 | 179 | 170 | 158 | ≤ 0.08 | ≤ 0.50 | ≤ 1.0 | ≤ 0.02 | 0.015 | 14.0 17.0 | ≥ 70 | Co≤ 1.0 Ti2.25-2.75 Fe 5.0-9.0 | |||||

| Ikhonkco X718 | -200 ukuba +600 | ≥ 1240 | 199 | 195 | 190 | 185 | 179 | 174 | 167 | 0.02 0.08 | ≤ 0.35 | ≤ 0.35 | ≤ 0.015 | 0.015 | 17.0 21.0 | 50.0 55.0 | V≤ 1.0Mo: 0.70-1.15 | |||||

| Nimonic 90 | -200 ukuba +700 | ≥ 1100 | 220 | 216 | 208 | 202 | 193 | 187 | 178 | ≤ 0.13 | ≤ 1.0 | ≤ 1.0 | ≤ 0.03 | 0.015 | 18.0 21.0 | UBhal | V15.0-21.0Mo:2.0-3.0 Al≤ 0.2 | |||||

♦♦♦ Ubushushu obuphezulu beMathiriyeli yaseNtwasahlobo Iimpawu: ♦♦♦

♦ I-304 yentsimbi engenasici

I-304 insimbi engenasici ikhubazeke kukusebenza okubandayo ukuphucula iimpawu zayo ezinwebekayo.Ayinakuqiniswa ngonyango lobushushu.Iya kuvelisa i-magnetism ngexesha lokusebenza okubandayo.I-304 yensimbi engenasici inokumelana ne-corrosion eyomeleleyo kunye neempawu ezintle zomzimba.

I-316 insimbi engenasici ikhubazeke ngokusebenza okubandayo ukuphucula iimpawu zayo ezinwebekayo, kwaye ayinako ukuqina ngonyango lobushushu.Iya kuvelisa i-magnetism ngexesha lokusebenza okubandayo.I-316 insimbi engenasici iqulethe i-molybdenum, enokumelana ne-corrosion enamandla kune-304 yensimbi engenasici, kwaye inokumelana nokubola kwizicelo zemichiza.

I-17-7PH ukuxhathisa okufanayo kwe-corrosion kwi-304 yensimbi engenasici, enokuthi iqhutywe ngonyango lobushushu kunye nokuqina kwemvula.Inokuqina okuphezulu kunye namandla emveliso.Ukusebenza kokukhathala kungcono kune-304 yensimbi engenasici kunye ne-65Mn carbon steel.Ikwane-elasticity entle phantsi kwe-℃ bume.

♦15-7Mo (GH632, 0Cr15Ni7Mo2Al)

I-15-7MoHas i-corrosion resistance resistance kwi-316 yensimbi engenasici.Inokugqithwa ngonyango lobushushu kunye nokuqina kwemvula.Inobunzima obuphezulu kunye namandla okuvelisa, kwaye ukusebenza kwayo kokukhathala kungcono kune-316 insimbi engenasici kunye ne-65Mn carbon steel.Ikwane-elasticity entle phantsi kwe-℃ bume.

I-Inconel X-750 yi-nickel-based precipitation lukhuni deformation superalloy.Isebenzisa ikakhulu i-r'phase njengenqanaba lokuguga lemvula enzima.Ubushushu obucetyiswayo bungaphantsi kwama-540℃.I-alloy inokumelana ne-corrosion kunye nokumelana ne-oxidation, kwaye inomsebenzi othile wokushisa ophantsi.

I-Inconel 718 yimvula esekwe nickel eyenza lukhuni deformation superalloy.Uluhlu lobushushu olucetyiswayo ngu -253--600℃.I-alloy inamandla aphezulu ngaphantsi kwe-600 ° C, inokumelana nokudinwa okulungileyo, ukuxhathisa kwi-radiation, ukumelana ne-oxidation kunye nokumelana nokubola, kunye nokusebenza kakuhle kokusebenza kunye nokuzinza kwexesha elide lesakhiwo.

I-alloy A-286 yi-iron-based precipitation ukuqina deformation ingxubevange yobushushu obuphezulu.Ubushushu bokusebenza obucetyiswayo bungaphantsi kwama-540℃.I-alloy inamandla aphezulu aphezulu kunye aphantsi obushushu kunye nokuzinza kwexesha elide, ukuxhathisa okulungileyo kwe-corrosion kunye nokusebenza kwe-thermal deformation, kwaye inokusebenza kakuhle kweplastiki kunye nokusebenza okwanelisayo kwe-welding.