Ucingo lweTitanium

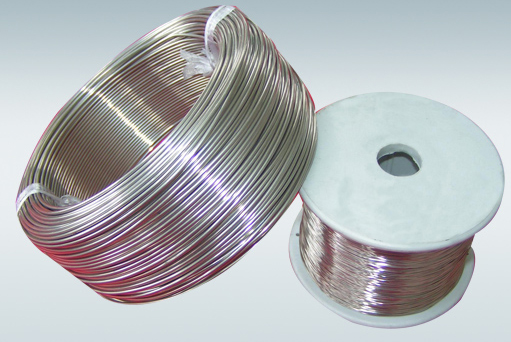

Ucingo lweTitaniumUcingo lwe-titanium luhlala lusetyenziselwa ukuwelda, iifreyimu, ukufakelwa kotyando, ukuhlobisa, ukuxhoma i-electroplating fixture.Isetyenziselwa ukuveliswa kwe-titanium powder e-spherical.

Ngocingo sebenzisa ibar ye-titanium okanye i-Titanium slab kwi-mold ukuba iqhube, ngenxa yesiphumo sokutsalwa, i-titanium bar ikhubaza phantsi kobushushu obuphezulu xa idlula kumngxuma wokungunda.Icandelo lomnqamlezo liyancitshiswa, kwaye ubude banda.Ukwelula kwimeko eshushu kunceda ukuphelisa uxinzelelo lwangaphakathi kunye nokuphucula iplastiki yeengcingo ze-titanium.Iphucula ngokufanelekileyo ukuchaneka kocingo lwe-titanium, kunye nokugqitywa komphezulu, onokuthi ufezekise ukusebenza kakuhle.

• Izixhobo zocingo zeTittanium: IBakala1, iBakala 2, iBakala 5, iBakala 5, iBakala7 , iBakala9, iBakala11, iBakala12, iBakala 16, iBakala23 ect

• Iifomu zocingo: I-Spool kwi-Coil, Sika ubude / ngokuthe tye

• Ububanzi: 0.05mm-8.0mm

• Iimeko:Isisombululo sifakwe kwi-Annealed, ukuqengqeleka okushushu, ukolula

• Umphezulu:I-Pickling White, Ikhazimlisiwe, i-Acid ihlanjwe, i-oxide emnyama

• Imigangatho:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 njl.

| I-Titanium Alloys Izinto eziphathekayo Igama eliqhelekileyo | ||

| Gr1 | I-UNS R50250 | CP-Ti |

| Gr2 | I-UNS R50400 | CP-Ti |

| Gr4 | I-UNS R50700 | CP-Ti |

| Gr7 | I-UNS R52400 | ITi-0.20Pd |

| G9 | I-UNS R56320 | I-Ti-3AL-2.5V |

| G11 | I-UNS R52250 | ITi-0.15Pd |

| G12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | I-UNS R52402 | I-Ti-0.05Pd |

| G23 | I-UNS R56407 | Ti-6Al-4V ELI |

♦ Ukuqulunqwa kweMichiza yeTitanium Wire ♦

| IBanga | Ukwakheka kweekhemikhali, ubunzima bepesenti (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye izinto Max.nganye | Ezinye izinto Max.iyonke | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦I-Titanum Alloy WireIiPropati zoMmandla ♦

| IBanga | Iimpawu ezibonakalayo | |||||

| Tensile strength Min | Unikeze Amandla Umz (0.2%, offset) | Ukwandiswa kwi-4D Ubuncinci (%) | Ukuncitshiswa kweNdawo Ubuncinci (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ I-Titanium Alloy Materials Materials: ♦♦♦

•IBanga loku-1: I-Titanium esulungekileyo, amandla aphantsi kakhulu kunye ne-ductility ephezulu.

•IBakala 2: Eyona titanium esulungekileyo isetyenziswa kakhulu.Eyona ndibaniselwano yamandla

•IBanga lesi-3: Amandla aphezulu e-Titanium, asetyenziselwa iipleyiti zeMatrix kwiqokobhe kunye nezitshintshi zobushushu ityhubhu

•IBanga lesi-5: Eyona alloy eyenziwe ngetitanium.Amandla aphezulu ngokugqithisileyo.ukumelana nobushushu obuphezulu.

•IBanga le-9: Amandla aphezulu kakhulu kunye nokumelana nomhlwa.

•IBanga le-12: Ukumelana nobushushu ngcono kuneTitanium esulungekileyo.Izicelo zeBakala 7 neBakala 11.

•IBakala 23: I-Titanium-6Aluminium-4Vanadium yokufakwa kokufakelwa kotyando.