I-AMS ASME ASTM ye-inconel625 i-alloy navigators

I-AMS ASME ASTM ye-inconel625 i-alloy navigators,

625 Alloy,Inconel 625 IiBars,Inconel 625 Rods,Inconel 625 sheet,Inconel 625 plate,Inconel 625 strip,Inconel 625 coil,

Amagama oRhwebo aqhelekileyo: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

I-Inconel Alloy 625 i-non-magnetic, i-corrosion kunye ne-oxidation resistant, i-nickel-chromium alloy.Amandla aphezulu e-Inconel 625 yisiphumo sokuhlanganiswa kokuqina kwe-molybdenum kunye ne-niobium kwisiseko se-nickel chromium ye-alloy.I-Inconel 625 inokumelana okumangalisayo noluhlu olubanzi lweendawo ezinobungozi ezingaqhelekanga ezibandakanya iziphumo zobushushu obuphezulu obufana ne-oxidation kunye ne-carburization.Amandla ayo agqwesileyo kunye nokuqina kwiqondo lokushisa ukusuka kubushushu be-cryogenic ukuya kwi-2000 ° F (1093 ° C) ithathwe ngokuyinhloko kwiziphumo eziqinileyo zesisombululo sesinyithi esiphikisayo i-Columbium kunye ne-molybdenum kwi-nickel-chromium matrix.

I-Inconel ye-625 ye-Chemical Composition

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Max. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 iiPropati zoMzimba

| Ukuxinana | 8.4 g/cm³ |

| Indawo yokunyibilika | 1290-1350 ℃

|

Inconel 625 iiPropati zoomatshini eziqhelekileyo

| Ubume | Tensile strength Rm N/mm² | Unikeze Amandla Rp 0. 2N/mm² | Ukwandisa Njenge % | Ukuqina kweBrinell HB |

| Unyango lwesisombululo | 827 | 414 | 30 | ≤220 |

Imigangatho ye-Inconel 625 kunye neNgcaciso

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE M3R, NACE M3

UNS N06625, Werkstoff 2.4856

| Ucingo | Iphepha | Ukuhluba | Intonga | Umbhobho | |

| AMS 5599, AMS 5666,AMS 5837, AMS 5979,ASTM B443 | I-ASTM B443 | AMS 5599, AMS 5979,ASTM B443 | I-ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Umbhobho ongenamthungo | Umbhobho odityanisiweyo |

| I-ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

I-Inconel 625 yeeMveliso ezifumanekayo kwiiNyithi zeSekonic

Inconel 625 yeBars & Rods

Imivalo engqukuva / imivalo eFlethi / imivalo yeHex, Ubungakanani ukusuka kwi-8.0mm-320mm, Isetyenziselwa iibholiti, iifastners kunye nezinye iindawo ezisecaleni

Inconel 625 intambo yokuwelda

Ukubonelela kwi-welding wire kunye ne-spring wire kwifom yekhoyili kunye nokusika ubude.

Inconel 625 sheet & plate

Ububanzi ukuya kuthi ga kwi-1500mm kunye nobude ukuya kuthi ga kwi-6000mm, Ukutyeba ukusuka kwi-0.1mm ukuya kwi-100mm.

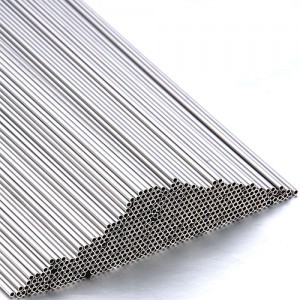

I-Inconel 625 ityhubhu engenamthungo kunye nombhobho odibeneyo

Ubungakanani bemigangatho kunye nobukhulu obulungiselelweyo bunokuveliswa ngathi ngokunyamezela okuncinci

Inconel 625 strip & coil

Imeko ethambileyo kunye nemeko enzima kunye nomgangatho oqaqambileyo we-AB, ububanzi ukuya kwi-1000mm

Inconel 625 Fasteners

I-alloy 625 sinokubonelela ngeebholiti, iiNti kunye nezinye iziqhoboshi njengeemfuno zabathengi

Iimpawu ze-Inconel 625 :

1.Amandla aphezulu okurhubuluza

2.I-Oxidation imelana ne-1800°F

3.Ukumelana nokudinwa okuhle

4.Weldability egqwesileyo

5.Ukumelana nokugqwesa kwi-chloride pitting kunye ne-crevice corrosion

6.I-Immune kwi-chloride ion stress corrosion cracking

7.Ukumelana namanzi olwandle phantsi kweemeko eziqukuqelayo nezimileyo naphantsi kobumdaka

Inconel 625 indawo yesicelo:

•Iinkqubo zokuhambisa iinqwelomoya

•Iinkqubo zokukhupha injini yeJet

•Iinkqubo ze-injini zokutyhalela umva

•Iimvumba kunye nokwandiswa kwamalungu

•Amakhonkco e-turbine shroud

•Iimfumba ezivuthayo

•Amacandelo amanzi olwandle

•Izixhobo zenkqubo yeekhemikhali zokuphatha iiasidi ezixubileyo zombini i-oxidizing kunye nokunciphisa.

Iifom zeeMveliso zenkampani yethu

Imivalo kunye neentonga

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Umbhobho ongenamthungo kunye neThubhu eWelded

Iityhubhu zeNickel/ Titanium Alloy, U-gobe / ityhubhu yokutshintsha ubushushu

IBolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Iphepha kunye neePlates

Hastelloy/Inconel/Incoloy/Cobalt/Tianium

Ukuqhawula kunye neFoil

I-Hastelloy/Inconel/ invar/ ii-alloys ezithambileyo zemagnethi ect

Imithombo yobushushu obuphezulu

Inconel 718/Inconel x750/ Nimonic 80A

ucingo & Welding

I-Cobalt Alloy wire, i-Nickel alloy wire, i-Tianium Alloy wire

IiFlange ze-alloy ezikhethekileyo

I-Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

IHanger ityhubhu ye-oyile

Inconel x750/ Inconel 718 /Monel 400 ect

I-Nickel Based Alloys

Izinto zokuwelda

Ii-alloys ezisekelwe kwiCobalt

Iintsimbi eziKhethekileyo ezingenazintsimbi

Ii-alloys ezichanekileyo

I-Titanium Alloys

Ngaba uyafuna ukufunda ngakumbi okanye ufumane isicatshulwa?

Dibana no

Yeyiphi imathiriyeli eyenziwe nge-625 alloy?I-nickel-based alloy ene-Ni-Cr ephezulu-Mo.

Ukubunjwa kwemichiza yeAlloy 625: Chromium (Cr) 20.0-23.0, Iron (Fe)< 5.0, (Al) & lt;0.4, Silicon (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni)258, sulfur (S)< 0.015, Cobalt (Co)< 1.0,(Mo)8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015,(Nb) 3.15-4.15, iCarbon (C)< 0.01.

I-625 Alloy ineempawu ezigqwesileyo ze-oxidation kunye nokumelana nomhlwa, ukomelela okugqwesileyo kunye nokuqina, ukumelana nokudinwa okugqwesileyo, ukubumbeka okuphezulu, kunye ne-weldability ebalaseleyo.Iyakwazi ukugcina amandla kunye nokuqina kwayo naphi na ukusuka kumaqondo obushushu asezantsi ukuya kuma-2000°F.Ngenxa yokuqina ngokukhawuleza kwe-alloy 625, isixa esikhulu sokwakheka okubandayo kunokufuna ukufakwa kwe-anneal kuyo yonke inkqubo yokubumba ebandayo.I-alloy isetyenziswa ngokuqhelekileyo kwiinjini zejethi kunye nezinye izicelo ze-aerospace.