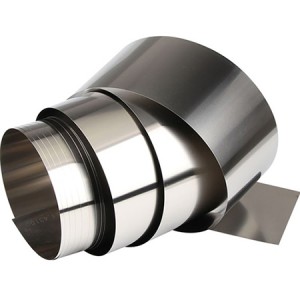

ERNiCrMo-3 Welding Wire Inconel 625 Welding Wire

I-ErNiCrMo-3(Inconel 625 UNSNO6625)Ucingo lwe-Welding

♦ Igama locingo lwe-Weliding: ErNiCrMo-3, Inconel 625 TIG/MIG Wire

♦ MOQ:15kg

♦ Ifom: MIG(15kgs/spool), TIG(5kgs/box)

♦ Ubungakanani:Ububanzi 0.01mm-8.0mm

♦ Ubungakanani obuqhelekileyo:0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

♦ Imigangatho:Iyahambelana neSiqinisekiso AWS A5.14 ASME SFA A5.14

ErNiCrMo-3esetyenziselwa ukuwelda 625 (N06625) ingxubevange, 20 ingxubevange, 825,25-6Mo, 9% Ni intsimbi okanye enye intsimbi molybdenum, ekwasetyenziselwa ukuwelda izinto ezahlukeneyo kunye nomhlwa ukumelana phezu komhlaba.

Iimpawu ezigqwesileyo zomatshini kumaqondo aphezulu kunye namaqondo aphantsi.Ukumelana ne-corrosion enamandla, uxinzelelo lwe-corrosion crack, i-pitting kunye ne-backlash corrosion kuluhlu olubanzi lwe-oxidation kunye nokunciphisa imidiya.

| C | Al | Si | Mn | Cr | Ni | Ti | Fe | S | Cu | Mo | P | Nb + Ta | Abanye |

| ≤0.10 | ≤0.40 | ≤0.50 | ≤0.50 | 20.0 - 23.0 | ≥58.0 | ≤0.40 | ≤5.0 | ≤0.015 | ≤0.50 | 8.0 - 10.0 | ≤0.02 | 3.15 - 4.15 | ≤0.50 |

| Ububanzi | Inkqubo | IVolt | Amps | Irhasi yokuKhusela | |

| In | mm | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | UTshintsho lokutshiza100% Argon |

| 0.045 | 1.2 | 28-32 | 180-220 | ||

| 1/16 | 1.6 | 29-33 | 200-250 | ||

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | 15-20 | 120-175 | ||

| 1/8 | 3.2 | 15-20 | 150-220 | ||

| Imeko | Ukuqina kokuqina kweMPa (ksi) | Isivuno Amandla eMPa (ksi) | Elongation% |

| AWS reauirement | 760(110) | Ayichazwanga ngqo | Ayichazwanga ngqo |

| Iziphumo eziqhelekileyo njengoko zidityanisiwe | 790(115) | 590(85) | 35 |

Kutheni i-ERNiCrMo-3?

Umxholo wentsimbi ephantsi, ungasetyenziswa ekudibaneni kwe-nickel-chromium molybdenum alloy,

Ingasetyenziselwa ukugquma kunye nokuwelda kweentsimbi ezisisiseko ezahlukeneyo ezifana ne-Ni-Cr-Mo ingxubevange enentsimbi engatyiwayo kunye nentsimbi yekhabhoni.

Inokumelana ne-oxidation elungileyo kunye nokunciphisa okusingqongileyo.

Umxholo ophezulu we-molybdenum unika uxinzelelo oluhle kunye nokuchasana nokugoba kunye nokuqhekekaumhlwa.

I-ERNiCrMo-3 Indawo yosetyenziso:

Ifanelekile ukuwelda kwe-nickel-chrome-molybdenum alloy, efana ne-Inconel625, i-Incoy 825, kwaye ingasetyenziselwa ukuwelda kunye ne-surfacing ye-nickel-base alloy kunye ne-stainless steel dissimilar materials.Ingasetyenziswa kwimekobume ukusuka kubushushu obuphantsi ukuya kuma 540℃.