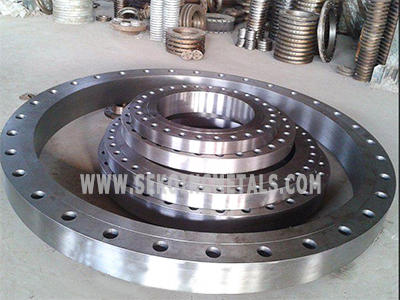

I-Incoloy 825 Flange

I-Incoloy 825 (W.Nr 2.4858) Flange

Flange Material :I-Incoloy Alloy 825 (UNS N08825)

Iintlobo zeFlange :Ngokweemfuno zabaxhasi

Umhla wokuzisa :15-30 iintsuku

Ixesha lokuhlawula :T/T, L/C, Paypal, Ect

I-Sekoinc Metals Main ivelisa kunye nokubonelela ngee-alloys ezikhethekileyo zeFlanges, samkela umyalelo wesampuli

Ingxubevange 825ngumxholo we-nickel ophezulu unika i-alloy esebenzayo yoxinzelelo lwe-corrosion cracking resistance.Ukumelana nokubola kuhle kwiindidi zeendaba, ezifana ne-sulfuric, i-phosphoric, i-nitric kunye ne-organic acids, isinyithi se-alkali ezifana ne-sodium hydroxide, i-potassium hydroxide kunye ne-hydrochloric acid solutions.

Ukusebenza okuphezulu okuphezulu kwe-Incoloy 825 kuboniswa kwi-disolver yokutsha kwenyukliya kunye neentlobo zeendaba ezitshabalalisayo, ezifana ne-sulfuric acid, i-nitric acid kunye ne-sodium hydroxide, zonke zicutshungulwa kwisixhobo esifanayo.

| Ingxubevange | % | Ni | Cr | Mo | Fe | C | Mn | Si | S | Cu | Al | Ti | P |

| 825 | Min. | 38.0 | 19.5 | 2.5 | 22.0 | - | - | - | - | 1.5 | 0.6 | - | |

| Max. | 46.0 | 23.5 | 3.5 | - | 0.05 | 1.0 | 0.5 | 0.03 | 3.0 | 0.2 | 1.2 | 0.03 |

| Ukuxinana | 8.14 g/cm³ |

| Indawo yokunyibilika | 1370-1400 ℃ |

| Ubume | Tensile strength Rm N/mm² | Unikeze Amandla Rp 0. 2N/mm² | Ukwandisa Njenge % | Ukuqina kweBrinell HB |

| Unyango lwesisombululo | 550 | 220 | 30 | ≤200 |

• Iintlobo zeFlange :

→ Iflange yepleyiti yokuwelda (PL) → Slip-on Neck Flange (SO)

→ Ukuwelda iflange yentamo (WN) → Iflange edibeneyo (IF)

→ I-socket welding flange (SW) → iflenge enemisonto (Th)

→ Iflange edibeneyo eqhinweyo (LJF) → iflenge eyimfama (BL(s)

♦ Izinto eziphambili zeFlange esizivelisayo

• Yenziwe ngentsimbi eshayinayo :I-ASTM A182

IBakala F304 / F304L, F316/ F316L, F310, F309, F317L, F321, F904L, F347

I-Duplex Stainless Steel: iBanga F44 / F45 / F51 / F53 / F55 / F61 / F60

• I-Nickel Alloys : I-ASTM B472, i-ASTM B564, i-ASTM B160

IMonel 400,I-Nickel 200, i-Incoloy 825, i-Incoly 926, i-Inconel 601, i-Inconel 718

I-Hastelloy C276, i-alloy 31, i-alloy 20, i-Inconel 625, i-Inconel 600

• I-Titanium Alloys :Gr1 / Gr2 / Gr3 / Gr4 / GR5/ Gr7 /Gr9 /Gr11 / Gr12

♦ Imigangatho:

ANSI B16.5 Class150,300,600,900,1500(WN,SO,BL,TH,LJ,SW)

DIN2573,2572,2631,2576,2632,2633,2543,2634,2545(PL,SO,WN,BL,TH)

I-Incoloy 825 yeeMveliso ezifumanekayo kwiiNyithi zeSekonic

Kutheni i-Incoloy 825?

I-825 i-alloy luhlobo lwe-alloy yobunjineli ngokubanzi, ene-asidi kunye ne-alkali yokumelana nokubola kwi-oxidation kunye nokunciphisa imeko kunye nokumelana okusebenzayo noxinzelelo lwe-corrosion cracking ngenxa ye-nickel ephezulu. i-asidi, i-phosphoric acid, i-nitric acid kunye ne-asidi ephilayo, kwi-alkali, njenge-sodium hvdroxide, i-potassium hvdroxide kunye ne-hvdrochloric acid isisombululo.Ukusebenza okuphezulu okubanzi kwe-825 alloy kubonisa kwisinyibiliki esivuthayo senyukliya se-corrosion medium eyahlukeneyo, efana ne-sulfuric acid, i-nitric acid kunye ne-sodium hvdroxide zonke ziphathwa ngesixhobo esinye.

•Ukumelana kakuhle noxinzelelo lwe-corrosion cracking.

•Ukuxhathisa kakuhle kwimingxuma kunye nokuhlwa kwemingxuma

•Ukuxhathisa okulungileyo kwi-oxidization kunye ne-non-oxidizing acid.

•Iipropati ezilungileyo zoomatshini kwiqondo lobushushu begumbi okanye ukuya kuthi ga kwi-550 ℃

•Isiqinisekiso sokwenza inqanawa yoxinzelelo lwe-450 ℃

I-Incoloy 825 Indawo yesicelo:

•Izinto ezinje ngee-coil zokufudumeza, iitanki, iikhreyithi, iibhaskithi kunye namatyathanga kwizityalo zokuchola zesulfuric acid.

•Izitshintshi zobushushu ezipholileyo zamanzi olwandle, iinkqubo zemibhobho yemveliso ekude nonxweme;iityhubhu kunye namacandelo kwinkonzo yegesi emuncu

•Izitshintshi zobushushu, i-evaporators, i-scrubbers, idiphu imibhobho njl.njl kwimveliso ye-asidi ye-phosphoric

•Izitshintshi zobushushu ezipholiswe ngumoya kwiindawo zokucoca i-petroleum

•Ukulungiswa kokutya

•Isityalo semichiza