Ifektri yokuvelisa umthombo we-Titanium mesh.Umnatha wocingo lwe-Titanium, umnatha we-titanium wonyango

Ifektri yokuvelisa umthombo we-Titanium mesh.Umnatha wocingo lwe-Titanium, umnatha we-titanium wonyango,

IBanga lesi-2, IBanga lesi-5, Ibanga le-11.Ibanga le-12.IBanga le-16, iBanga23, Ibanga lesi-7, Ibanga lesi-9, Ibanga, TA2, TAL, TC4,

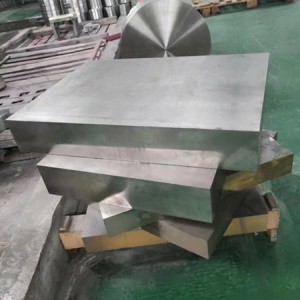

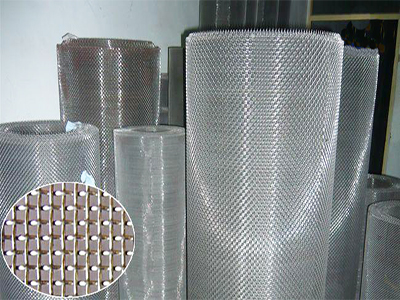

I-Titanium Mesh:I-Titanium Mesh eyenziwe ngeengcingo ze-Titanium Alloys, inkampani yethu idityaniswe nomzi-mveliso we-Mesh eyandisa uluhlu lwemveliso kwiimveliso zocingo ezinenatha kunye neemveliso ezenziweyo.sineminyaka emininzi yamava kwimveliso ye-wire mesh, kwaye i-titanium mesh eveliswayo ineempawu zokuzinza kunye nokusebenza kakuhle kokucoca.

• Iintlobo:

→ Umnatha wokulukwa ongenanto → Umnatha ophothiweyo

→ Umnatha wokulukwa oqalekisiweyo → umnatha wokuluka waseDatshi

• Inkcazo: I-1 mesh-100 mesh

Imigangatho ye-ASTM ilandelwa ekuvelisweni kweengcingo zocingo.Ubalulo lwemesh olukhoyo lusukela kobunzima kakhulu ukuya kolucolekileyo kakhulu.Owona mnatha unzima wenziwa ngocingo oluyi-8.0mm ngelixa eyona mesh igqwesileyo yenziwe ngocingo oluyi-0.03mm olune-360mesh/intshi.

• Izicelo:I-Titanium wire mesh ingasetyenziswa kwizihluzi ezixhathisa ubushushu obuphezulu, ukwakhiwa kweenqanawa, ukwenziwa komkhosi, izihluzi zekhemikhali, izihluzi zoomatshini, iminatha yokukhusela i-electromagnetic, izihluzi zokucoca amanzi olwandle, izihluzi zokucoca ubushushu bombane, izihluzi zeoyile, ukusetyenzwa kokutya, ukuhluzwa kwezonyango.

| I-Titanium Alloys Izinto eziphathekayo Igama eliqhelekileyo | ||

| Gr1 | I-UNS R50250 | CP-Ti |

| Gr2 | I-UNS R50400 | CP-Ti |

| Gr4 | I-UNS R50700 | CP-Ti |

| Gr7 | I-UNS R52400 | ITi-0.20Pd |

| G9 | I-UNS R56320 | I-Ti-3AL-2.5V |

| G11 | I-UNS R52250 | ITi-0.15Pd |

| G12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | I-UNS R52402 | I-Ti-0.05Pd |

| G23 | I-UNS R56407 | Ti-6Al-4V ELI |

♦ I-Titanium Alloys Ukubunjwa kweMichiza ♦

| IBanga | Ukwakheka kweekhemikhali, ubunzima bepesenti (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye izinto Max.nganye | Ezinye izinto Max.iyonke | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ IiPropati zePhysical ye-Titanum Alloy ♦

| IBanga | Iimpawu ezibonakalayo | |||||

| Tensile strength Min | Unikeze Amandla Umz (0.2%, offset) | Ukwandiswa kwi-4D Ubuncinci (%) | Ukuncitshiswa kweNdawo Ubuncinci (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

Umnatha we-Titanium usetyenziswa ikakhulu kwi-asidi, iimeko ze-alkali zokusingqongileyo kunye nokuhluzwa okanye igesi, ukuhluzwa kolwelo kunye nokwahlulwa kwemidiya.Zine iindlela zokulukwa okucacileyo, i-twill weave, i-pre-crimp weave kunye ne-Dutch weave.Saikang Metal Technology Co., Ltd. uzimisele ukubonelela abathengi ngemveliso / iinkonzo ezisemgangathweni.Ukuba unomdla kwiimveliso kunye neenkonzo zethu, nceda uqhagamshelane nathi kwaye ujonge phambili kwimpendulo yakho.