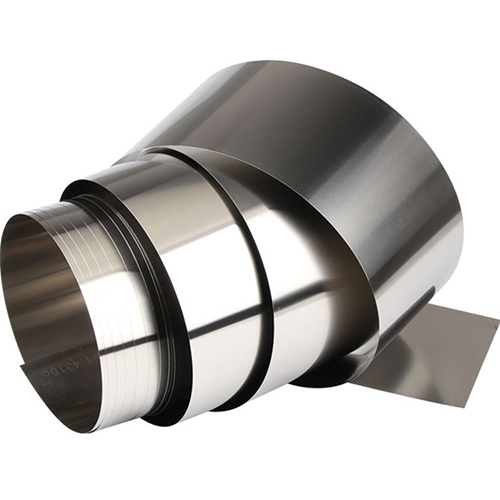

Umcu we-Titanium, ubunyulu obuphezulu be-titanium foil

Uluhlu lwe-Titanium,ukucoceka okuphezulu kwe-titanium foil,

IBanga lesi-2, IBanga lesi-5, IBanga lesi-7 kunye neBanga lesi-9, Ibanga, ukucoceka okuphezulu kwe-titanium foil, I-titanium yonyango, I-Titanium Strip, I-Tittanium Strip kunye ne-Foil Materials: I-Titanium ecocekileyo (CP) kunye ne-Titanium alloy foil,

• I-Tittanium Strip kunye ne-Foil Materials: I-Titanium ecocekileyo (CP) kunye nefoyile ye-Titanium alloy, iBakala1,IBanga lesi-2, IBanga lesi-5, iBanga lesi-5,IBanga lesi-7 kunye neBanga lesi-9

• Iifomu: Umtya omnye, kwikhoyili, okanye kwi-spool.Inkonzo yokusika iyafumaneka

• Umda:Ukutyeba: ≥0.01mm : 20~1000mm, Ubude: Njengesicelo

• Iimeko:Ukuqengqeleka okubandayo(Y)~Kushushu kuqengqeleka(R)~I-Annealed (M)~Isimo esiSolid

• Imigangatho:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 njl.

• Iinkqubo:I-Electronics, iikhemikhali, iiwotshi, iiglasi, ubucwebe, iimpahla zemidlalo, oomatshini, izixhobo zokucola, izixhobo zokusingqongileyo, igalufa kunye nemizi-mveliso yomatshini yokuchaneka.

| I-Titanium Alloys Izinto eziphathekayo Igama eliqhelekileyo | ||

| Gr1 | I-UNS R50250 | CP-Ti |

| Gr2 | I-UNS R50400 | CP-Ti |

| Gr4 | I-UNS R50700 | CP-Ti |

| Gr7 | I-UNS R52400 | ITi-0.20Pd |

| G9 | I-UNS R56320 | I-Ti-3AL-2.5V |

| G11 | I-UNS R52250 | ITi-0.15Pd |

| G12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | I-UNS R52402 | I-Ti-0.05Pd |

| G23 | I-UNS R56407 | Ti-6Al-4V ELI |

I-Titanium Stripkunye neFoil:Sinika ubukhulu becala i-titanium Strip ecocekileyo yeGr1, Gr2, Gr4 amabanga;Kwi-titanium alloy Foil, Sibonelela ikakhulu i-Gr5, i-Gr7, i-Gr9, i-Gr11, i-Gr12, i-Gr16, i-Gr23 kunye namanye amabanga, ziveliswa ngesiseko sepleyiti ye-titanium kunye nokuqengqeleka okubandayo;inkqubo yokuvelisa i-titanium sheet inzima ngakumbi.Ulawulo lwe-deformation lungqongqo ngakumbi kwinkqubo yokuqengqeleka.Oko kunokunqunyulwa ngobukhulu obuhlukeneyo ngokweemfuno zomthengi, ukunciphisa kakhulu ixesha lokunikezelwa.

♦ I-Titanium Strip Ukuqulunqwa kweekhemikhali ♦

| IBanga | Ukwakheka kweekhemikhali, ubunzima bepesenti (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye izinto Max.nganye | Ezinye izinto Max.iyonke | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Strip Iipropati zePhysical♦

| IBanga | Iimpawu ezibonakalayo | |||||||

| Tensile strength Min | Amandla esivuno ubuncinane (0.2%, offset) | Ukwandiswa kwi-4D Ubuncinci (%) | Ukuncitshiswa kweNdawo Ubuncinci (%) | Uvavanyo lokugoba (iRadius yaseMandrel) | ||||

| ksi | MPa | ksi | MPa | <1.8mm Kwiingqimba | 1.8-4.8mm Ubukhulu | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Iimpawu: ♦ ♦ ♦

•IBanga loku-1: I-Titanium esulungekileyo, amandla aphantsi kakhulu kunye ne-ductility ephezulu.

•IBakala 2: Eyona titanium esulungekileyo isetyenziswa kakhulu.Eyona ndibaniselwano yamandla

•IBanga lesi-3: Amandla aphezulu e-Titanium, asetyenziselwa iipleyiti zeMatrix kwiqokobhe kunye nezitshintshi zobushushu ityhubhu

•IBanga lesi-5: Eyona alloy eyenziwe ngetitanium.Amandla aphezulu ngokugqithisileyo.ukumelana nobushushu obuphezulu.

•IBanga lesi-7: Ukumelana ne-corrosion ephezulu ekunciphiseni kunye neendawo ze-oxidizing.

•IBanga le-9: Amandla aphezulu kakhulu kunye nokumelana nomhlwa.

•IBanga le-12: Ukumelana nobushushu ngcono kuneTitanium esulungekileyo.Izicelo zeBakala 7 neBakala 11.

•IBakala 23: I-Titanium-6Aluminium-4Vanadium ELI (I-Interstitial Eyongeziweyo ephantsi) I-alloy yokufakelwa kwesicelo sotyando.

I-Sekonic Metals Technology Co., Ltd ibonelela ngepleyiti yetitanium, intonga yetitanium, i-titanium capillary, isikrufu setitanium, isiqhoboshi setitanium, intonga yocingo lwetitanium, i-titanium nut, iinxalenye ezimile... iimveliso kunye neenkonzo nceda uqhagamshelane nathi, sijonge phambili kwimpendulo yakho