I-MONEL Alloy K-500 (UNS N05500 / WR2.4375) i-alloy ye-nickel-copper edibanisa iingenelo zokumelana nokugqwesa okugqwesileyo ngamandla amakhulu kunye nobunzima be-MONEL alloy 400. I-aluminium kunye ne-titanium yongezwa kwisiseko se-nickel-copper kwaye ishushu. phantsi kweemeko ezilawulwayo ukunyusa i-submicroscopic ye-Ni3 (Ti, AI) iinqununu kuyo yonke isiseko se-nickel-copper, ngaloo ndlela iphucula i-matrix yokusebenza.Ukusetyenziswa komsebenzi oshushu ukufezekisa umphumo wemvula ihlala ibizwa ngokuba kukuguga lukhuni okanye ukuguga.

Usetyenziso oluqhelekileyo lwe-MONEL alloy K-500 iimveliso ziyikhonkco kunye nezibophelelo zentambo kunye nemithombo.

Iinkonzo zaseLwandle: Iimpompo kunye neendibano zevalvu,

Unyango lweMichiza: ukucutshungulwa kwe-pulp ekuvelisweni kwephepha kumagqabi ogqirha kunye ne-scrapers;

I-oyile ye-drilling kunye nezixhobo zokusebenza, i-shaft yepompo kunye ne-impeller, izindlu ezingenamagnetic, ukuphakama kokhuseleko kunye nevalve yeoli kunye nokuveliswa kwegesi yendalo;Kwaye abenzi boluvo kunye nezinye izixhobo ze-elektroniki.

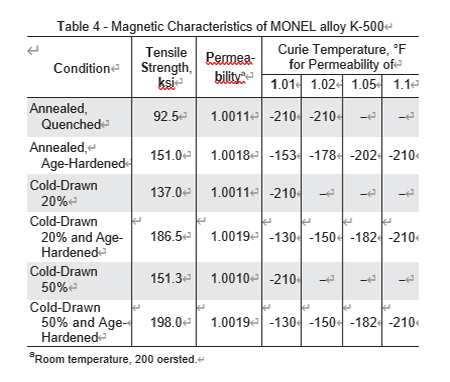

Enye yeepropathi zeMonel K500 alloy kukuba ayinamagnetic, nokuba kubushushu obuphantsi kakhulu.Nangona kunjalo, kunokwenzeka ukwenza umaleko wamagnetic kumphezulu wezinto eziphathekayo ngexesha lokucubungula.I-aluminiyam kunye nobhedu zinokukhethwa ngokufanelekileyo nge-oxidized ngexesha lokufudumeza, ukushiya ifilimu ene-nickel ecebileyo yamagnetic ngaphandle kwephepha.Esi siphumo sivakaliswa ngokukodwa kucingo olubhityileyo okanye umcu onomphezulu ophezulu wobunzima bomlinganiselo.Ifilimu yamagnetic isuswa ngokukhethwa okanye i-acid leaching ekhanyayo ukubuyisela iimpawu ezingezizo zemagneti zezinto.Ukudityaniswa kokungena okuncinci, amandla aphezulu, kunye nokumelana nokugqwesa okugqwesileyo kusetyenziswe kwizicelo ezininzi, ngakumbi izixhobo zokulinganisa kakuhle kunye nezinto zombane.

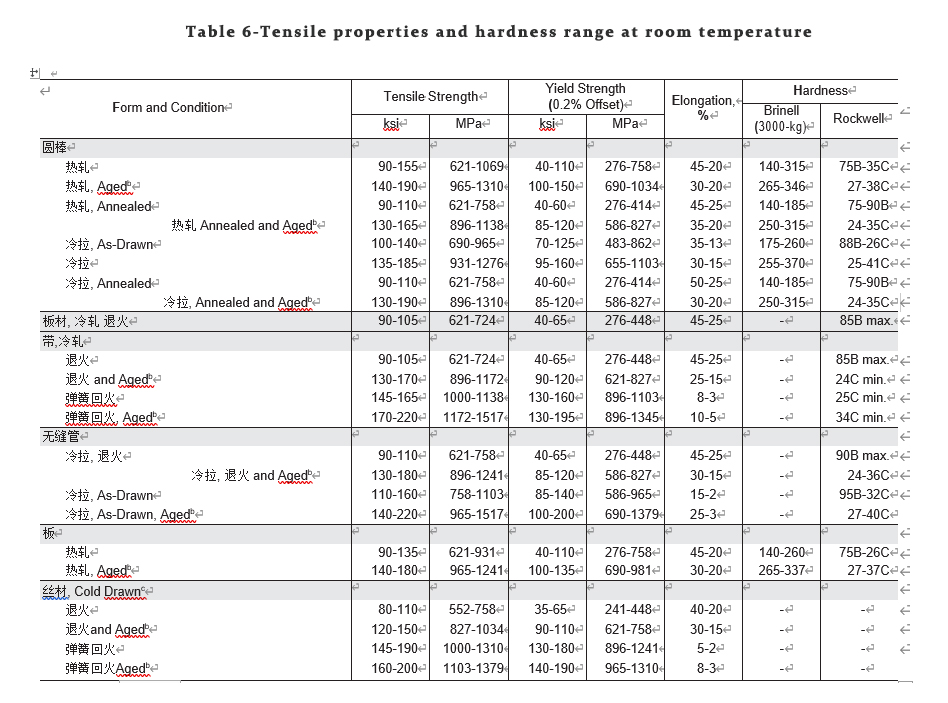

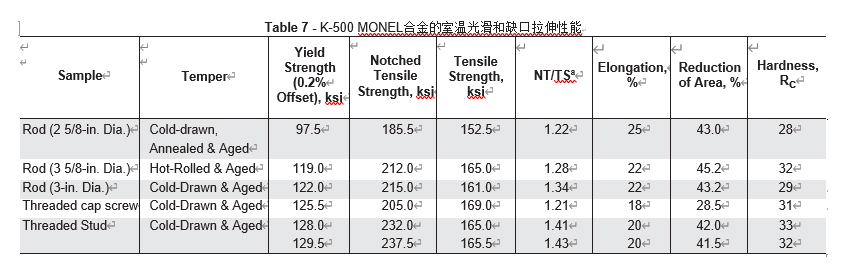

Kufunyenwe ukuba i-alloy ye-Monel K-500 inozinzo oluhle kakhulu lwe-dimensional kuvavanyo lokuvezwa kwexesha elide kunye novavanyo lokujikeleza.Le propati ye-alloy ivumela ukuba isetyenziswe kwizixhobo ezichanekileyo eziphezulu ezifana ne-gyros.Uluhlu lweempawu zokuqina kunye nokuqina kwiqondo lobushushu begumbi kuboniswe kwiTheyibhile 6. Ubudlelwane obusondeleyo phakathi kweempawu zokuxinana kunye nobunzima bemivalo kunye nokukhwabanisa kubonakala kwiFig.I-4 kunye ne-5, kunye nobudlelwane obufanayo bamashiti kunye nemicu buvela kuMfanekiso 6. Itheyibhile 7 ithelekisa ukusebenza kwenotshi yeesampuli ezigudileyo.Ixesha elifutshane kunye neempawu zokushisa eziphezulu ze-K500 ze-alloy bars phantsi kweemeko ezahlukeneyo ziboniswe kumzobo ongezantsi.Izibonda ezishushu ezigqityiweyo zavavanywa ngesantya se-0.016 intshi / min ngokusebenzisa amandla okuvelisa kunye ne-0.026 intshi / min ukusuka apho ukuphuka.Iisampuli ezifakwe kwi-cold-drawn zavavanywa kumandla okuvelisa i-0.00075 intshi / min, ilandelwa yi-0.075 intshi / min.

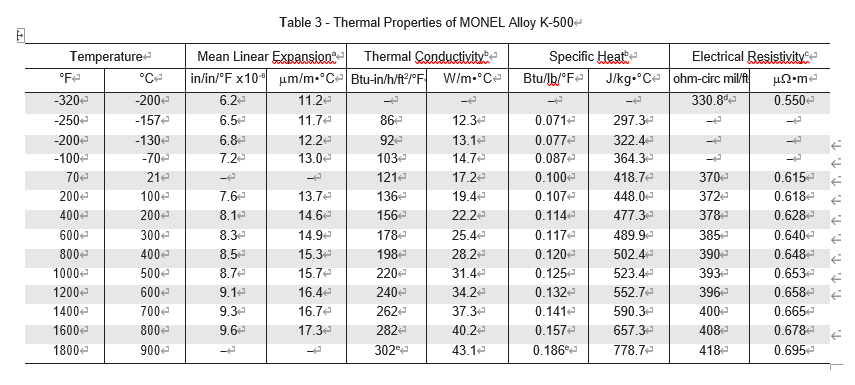

I-alloy ye-K-500 ye-Monel inentsebenzo ebalaseleyo yobushushu obuphantsi.Amandla okuqina kunye namandla esivuno anyuka ngokuhla kweqondo lobushushu, ngelixa iplastiki kunye nokuqina kuphantse kungachaphazeleki.Nakumaqondo obushushu asezantsi njenge-hydrogen elulwelo, inguqu ukusuka eqinile ukuya kwibrittle ayenzeki.Ngoko ke, i-alloy ifanelekile kwizicelo ezininzi zokushisa eziphantsi.Ukusebenza kwesiseko sentsimbi ye-K-500 ye-alloy kunye ne-welded sheet metal kwi-423 ° F ibonisiwe.Ukuba unyango lokuguga luqhutywa emva kwezixhobo zokutshisa i-welding, i-weld kunye namandla okuguga lukhuni isiseko sesinyithi ngaphandle kokulahlekelwa okukhulu kwe-ductility inokufumaneka.I-welding yezinto eziqiniweyo zeminyaka kufuneka igwenywe ngenxa yokuba i-ductility yabo iyancipha kakhulu.

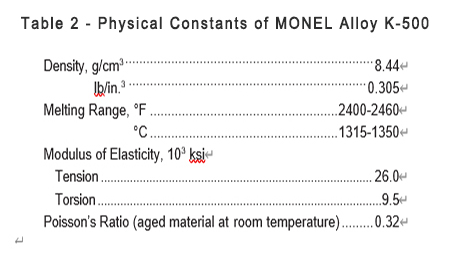

I-MONEL alloy K-500 ikhethwe njenge-UNS N05500 kunye ne-Werkstoff NR.2.4375.Idweliswe kwiiNkonzo ze-NACEMR-01-75 ze-Oli kunye neGesi.I-alloy K-500 ifumaneka kuluhlu olubanzi lweefom zokusila eziqhelekileyo ezibandakanya ityhubhu, ityhubhu, ipleyiti, i-strip, ipleyiti, i-bar ejikelezayo, i-flat bar, i-forgings, i-hexagon kunye nocingo.Icwecwe, iPhepha kunye neStrip -BS3072NA18(Plate and strip),BS3073NA18(Strip),QQ-N-286(Plate, sheet and Strip),DIN 17750(Plate, Sheet and strip),ISO 6208(Sheet, Sheet and Strip) Imivalo, iMivalo, iiNcingo kunye neeNgxoxo -BS3075NA18 (Ucingo), BS3076NA18 (Induku kunye nentonga), i-ASTM B 865 (Intonga kunye nentonga), DIN 17752 (Induku kunye nentonga), DIN 17753 (Ucingo), DIN 17754 (Forgings),QQ -N-286(Intonga, intonga, ucingo kunye Forgings), SAE AMS 4676(Iintonga kunye neentonga),ASME Code Case 1192(Iintonga kunye neentonga),ISO 9723(iinduku),ISO 9724(Wire),ISO9725(Forgings) Imibhobho kunye neMibhobho -BS3074NA18 (Iibhubhu ezingenamthungo kunye neetyhubhu), i-DIN 17751 (Iibhubhu kunye neebhubhu) Ezinye iimveliso -DIN 17743 (I-Chemical Composition), i-SAE AMS 4676 (i-Chemical composition), i-QQ-N-286 (i-Chemical composition)

Ixesha lokuposa: Sep-20-2022

- Okulandelayo: Iqela leZinyithi zeSekonic kuThintelo noLawulo lwe-Epidemic

- Ngaphambili: {Ukwaziswa kwemveliso} N08020